por

Lauren Dubinsky, Senior Reporter | October 04, 2017

Plans to grow its additive business

to $1B by 2020

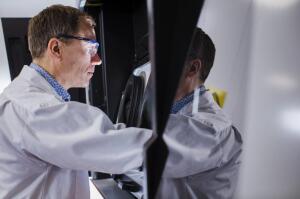

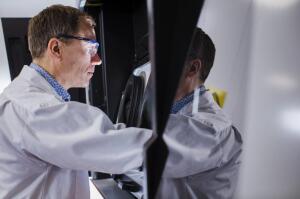

GE Healthcare recently opened its first European 3-D printing and design center in Uppsala, Sweden.

"Additive manufacturing has been hailed the fourth industrial revolution, because of its potential to improve product design and manufacturing efficiency," Andreas Marcstrom, manager of additive engineering at the new Innovative Design and Advanced Manufacturing Technology Center, told HCB News.

The center will use metal and polymer 3-D printers and robotic technology to speed up the development of new products. Its research and design teams will work with advanced manufacturing engineers and customers to design, test and produce 3-D-printed parts for GE products.

GE decided to build the center in Uppsala because the area offers the infrastructure and expertise it needs to succeed.

"The center is at the heart of the biggest research and development organization within GE Healthcare Life Sciences — 400 people," said Marcstrom. "At the same facilities, you have teams with post-processing expertise as well as global supply chain and manufacturing."

Close by in Umeå, Northern Sweden, there is also a hardware manufacturing facility for GE's Life Sciences' BioProcess business. The teams from all of these areas of expertise will collaborate on projects at the new center.

According Marcstrom, the use of 3-D printers has the potential to cuts costs and improve the company's supply chain and products. For instance, a 3-D-printed part can combine 20 parts into a single part and improve performance.

That's especially beneficial for the biomanufacturing industry since the manufacturing equipment is made up of hundreds of different parts. GE is currently working with Amgen to evaluate the performance of a 3-D-printed, custom-designed chromatography column. This tool is used to develop biopharmaceuticals for cancer and immune disease.

It's being tested to determine if it can be used in Amgen's research to help develop better processes for the purification stage of biopharmaceutical production.

The team at the center is also developing and programming multiple robots called cobots. They have already been installed in GE's factories around the world to improve the efficiency of production lines.

GE has another advanced manufacturing engineering center based in Milwaukee, Wisconsin. The teams at both centers will share knowledge and collaborate on new design ideas.

Globally, the 3-D printed medical devices market is booming. A MarketsandMarkets

report from August predicted that it will grow from $840 million in 2017 to almost $1.9 billion by 2022.

GE has big plans for this market. The company is seeking to grow its new additive business to $1 billion by 2020. It plans to sell 10,000 additive machines over the next 10 years.