por

Lauren Dubinsky, Senior Reporter | October 17, 2022

From the October 2022 issue of HealthCare Business News magazine

Lead is the go-to material for radiation shielding for a reason. It’s high-density, low-cost and has excellent attenuation. The downside is that this material can lead to significant health problems if it’s ingested or inhaled.

Although there is no dispute that lead is toxic, studies investigating the effect of lead exposure on radiology personnel have produced conflicting findings. A study published last year in the Archives of Environmental & Occupational Health collected hand dust wipe and blood samples from 58 radiology department workers in an academic hospital.

The research team did not find an elevated risk of lead contamination on the study participants’ hands or in their blood. They concluded that although the sample size was small, lead poisoning is “unlikely to occur with high frequency in lead shield users.”

Another study from last year revealed that radiographers working in radiological departments in general hospitals had significantly higher concentrations of lead in their scalp hair than administrative staff. The study, which was published in Nature Research, also found that the mean lead concentration in their hair was comparable with that of workers in lead-related manufacturing plants.

Lead alternatives made of tungsten and bismuth were developed in an attempt to avoid those risks. But those products come with higher price tags and that has hampered their growth in the market.

"The problem with the company that was making this non-lead-based shielding material is they can never get down to the price point,” said Adam Evearitt, co-owner of Atom Physics. “There are very few people that, when push comes to shove, aren't aren't going to make decisions based on price."

In July, a research team based in Egypt announced that it developed a 3D-printing technique for creating light bismuth radiation shielding material. The material is made up of micro and nano bismuth particles between layers of polylactic acid thermoplastic polymer.

“The challenge with bismuth is that it is much more expensive than lead and the lower-density factor requires thicker shielding,” said Kevin Milne, president and CEO of MarShield. “In most cases up to five times the thickness of lead is required to achieve the same shielding.”

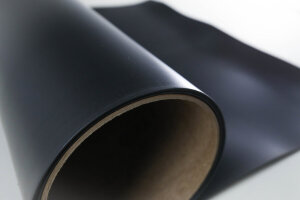

MarShield offers a non-lead shielding product called FlexShield XYZ, which is polymer-based and can be made into thin materials to replace sheet lead. It comes in different formulations including tungsten, bismuth or iron, but tungsten is what is mostly in demand.